PRODUCTS

Automatic backwash filter

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

Product introduction

Automatic backwash filter is suitable for various water supply systems, process water systems and industrial cooling water systems, especially for 24-hour non-stop systems, which can filter out various mechanical impurities in water and ensure system equipment. safe and reliable operation.

Structure and working principle

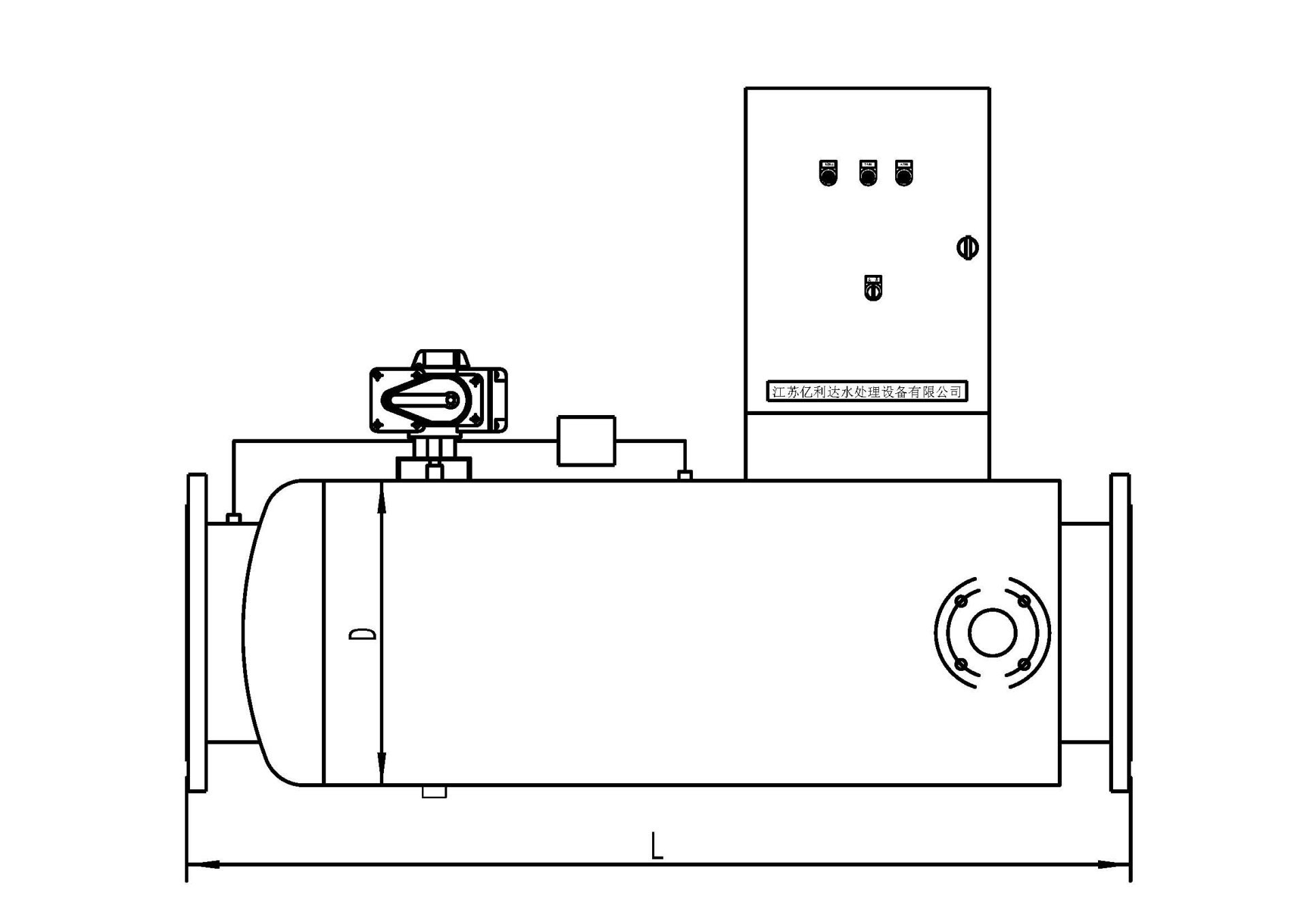

The automatic backwash filter is mainly composed of high-quality carbon steel cylinder, stainless steel wedge-shaped filter screen with special structure, electric actuator and sewage device. When the filter is working, the electric actuator guides the butterfly valve to be in an open state, and the water flow enters the filter from the inlet, and is filtered to the outlet through the filter screen. When the filter needs to discharge sewage, close the butterfly valve and open the sewage valve. The water flows through the first half of the filter screen to filter, part of the water flow enters the system from the outlet, and the remaining water flow flows from the outside of the second half of the filter screen to the inside, and is discharged through the sewage outlet. The function of automatically flushing the filter screen. In this way, the entire flushing process system can work normally without downtime.

Technical parameters

※Working pressure: ≤1.0MPa

※Working temperature: ≤100℃

※Pressure loss: ≤0.015MPa

※Filter precision: d=1.0mm

Others: The working pressure, filtration accuracy and specifications can be specially manufactured according to user requirements.

Selection reference table

| model |

flow |

Exit and entry diameter |

Sewage diameter(mm) |

D (mm) |

L |

weight |

|

|

mm |

in |

||||||

|

YL-2PZ |

19 |

50 |

2 |

25 |

159 |

500 |

50 |

|

YL-2.5PZ |

28 |

65 |

2.5 |

25 |

159 |

500 |

50 |

|

YL-3PZ |

50 |

80 |

3 |

25 |

219 |

550 |

60 |

|

YL-4PZ |

80 |

100 |

4 |

25 |

219 |

600 |

70 |

|

YL-5PZ |

125 |

125 |

5 |

25 |

219 |

650 |

80 |

|

YL-6PZ |

180 |

150 |

6 |

32 |

273 |

800 |

100 |

|

YL-8PZ |

320 |

200 |

8 |

40 |

325 |

900 |

150 |

|

YL-10PZ |

490 |

250 |

10 |

50 |

377 |

1050 |

180 |

|

YL-12PZ |

710 |

300 |

12 |

65 |

426 |

1100 |

200 |

|

YL-14PZ |

970 |

350 |

14 |

65 |

478 |

1200 |

266 |

|

YL-16PZ |

1260 |

400 |

16 |

65 |

530 |

1350 |

350 |

|

YL-18PZ |

1590 |

450 |

18 |

80 |

630 |

1500 |

445 |

|

YL-20PZ |

1970 |

500 |

20 |

100 |

720 |

1700 |

500 |

|

YL-24PZ |

2850 |

600 |

24 |

125 |

800 |

1900 |

620 |

The above data is for reference only, and the data of each product shipped shall prevail.

Technical Features

1. High filtration precision and stable effluent quality.

2. Through its own retrieval and response functions, it can realize automatic backwashing, which can cope with unstable water quality fluctuations without manual intervention.

3. The control system is sensitive in response and accurate in operation. It has dual setting functions of differential pressure and time, and can flexibly adjust the setting value of differential pressure or time for backwashing according to different water sources and filtration precision.

4. It does not interrupt normal water production during backwashing, runs continuously, and is stable and reliable.

5. The duration of backwashing is short, and the water consumption of backwashing is only 0.001-0.002% of the normal water production, saving water, electricity and energy.

6. The structure design is compact and reasonable, the floor area is small, and the installation and movement are flexible and convenient.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible