PRODUCTS

Full procedures comprehensive water processor

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

product description

It has been proved by long-term practice that there are four main hazards in today's water systems, including scaling, corrosion, sludge, and microbial reproduction. The water quality problems of water systems, especially circulating water systems, are often comprehensive. The water treatment equipment used in the past cannot be solved due to the limitation of the function of a single equipment, so it needs to be solved through further practical technology. Our company designs and manufactures a comprehensive water processor by using a combination of high-frequency technology and electric power magnetic field effect, aiming at different problems of electrochemical corrosion, scaling, bacteria and algae reproduction, using a combination of multiple frequency bands and electrostatic high voltage.

working principle

The integrated water processor first adopts high-frequency technology, and uses the action of high-frequency electric field to activate water, the movement speed of Ca2+ and Mg2+ ions in the water is reduced, the number of effective collisions with CO32- and SO32- plasma in the water is reduced, and the electrostatic attraction is reduced. Therefore, the heated wall or pipe surface cannot be scaled, so as to achieve the purpose of scale prevention. The high-frequency electromagnetic field increases the penetration force and solubility of the force, and penetrates the weak links of the scale on the metal surface longitudinally into the metal surface, and then begins to penetrate laterally along the surface of the metal and the scale, so that the scale is separated from the metal surface in flakes, so as to achieve descaling the goal of. The micro-electric environment can curb the growth of microorganisms and destroy their living environment. In addition, the active oxygen free radicals generated during the working process of the equipment can damage biological macromolecules and change the biological field where bacteria and algae live to achieve sterilization and algae killing. Purpose. Secondly, the composite filtration system (surface filtration principle, multi-media composite layer, electric magnetic field effect) is used to adsorb and capture suspended iron and manganese ions, bacteria and algae colloids in the water and discharge the system to achieve the effect of ultra-clean filtration.

technical parameter

① Control corrosion rate: <0.01mm/year

② Pressure loss: <0.03~0.06Mpa

③ Working voltage: AC 160V~240V

④ Safe insulation voltage: 5000V

⑤ Power consumption: <120W~600W

⑥ Working environment requirements: temperature -25℃~+50℃, relative temperature <95%

⑦ Working temperature (temperature of the treated medium): -25℃~+50℃

⑧ Average trouble-free working time: not less than 50,000 hours

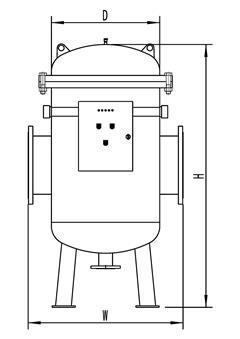

Selection reference table

| model |

flow (T/h) |

Exit and entry diameter (mm) |

Sewage diameter (mm) |

D (mm) |

H (mm) |

W (mm) |

net weight (Kg) |

|

YS-50 |

10-18 |

50 |

25 |

325 |

700 |

525 |

175 |

|

YS-80 |

18-45 |

80 |

25 |

325 |

850 |

525 |

195 |

|

YS-100 |

45-70 |

100 |

32 |

377 |

850 |

577 |

265 |

|

YS-125 |

70-130 |

125 |

32 |

426 |

1050 |

626 |

120 |

|

YS-150 |

130-158 |

150 |

40 |

426 |

1050 |

626 |

310 |

|

YS-200 |

158-280 |

200 |

40 |

530 |

1350 |

730 |

585 |

|

YS-250 |

280-440 |

250 |

50 |

530 |

1350 |

730 |

760 |

|

YS-300 |

440-640 |

300 |

50 |

630 |

1500 |

830 |

1085 |

|

YS-350 |

640-865 |

350 |

65 |

720 |

1700 |

920 |

1135 |

|

YS-400 |

865-1130 |

400 |

80 |

720 |

1700 |

920 |

1770 |

|

YS-450 |

1130-1430 |

450 |

100 |

800 |

1800 |

1000 |

2200 |

|

YS-500 |

1430-1800 |

500 |

100 |

800 |

1800 |

1000 |

2315 |

|

YS-600 |

1800-3000 |

600 |

100 |

900 |

2100 |

1200 |

700 |

|

YS-700 |

3000-4800 |

700 |

125 |

1000 |

2200 |

1300 |

850 |

The above data is for reference only, and the data of each product shipped shall prevail.

Equipment operation

① In order to facilitate the installation and maintenance of the equipment, the top of the main body and the outermost outer diameter should be more than 400mm away from other equipment.

② It is forbidden to turn on the device for a long time without water.

③ The equipment should be installed by bypass to meet the needs of overhauling the equipment and backwashing the filter body without stopping the machine.

④ Sewage discharge rate: When the new system is used for the first time, it should be backwashed 1-2 times a day. After normal operation, backwash is performed when the pressure difference between the inlet and outlet reaches 0.03-0.06Mpa. For systems with serious pollution, backwash with gas and water should be used.

⑤ Backwash: open the main valve, the drain valve, close the water inlet valve of the equipment, and backwash the filter body. The backwashing time depends on the water quality, generally about 30 seconds.

⑥ After the filter body is revived, the pressure difference between the inlet and outlet returns to the original pressure difference value, open the water inlet valve, close the main valve, the drain valve, and connect the 220V power supply to make the equipment work normally.

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible