PRODUCTS

Magnetic Water Treatment

Gategory:

Key words:Water Filter、UV Sterilizer、Ion Exchange Water softener

The internal magnetic water processor uses the magnetic field to treat the water and changes the physical structure of the water without changing the chemical composition of the water, so as to achieve the purpose of anti-scaling, descaling, sterilization, algae killing, anti-corrosion and anti-rust water. . This is a physical method of water treatment, with good effect, low cost, no maintenance and no pollution. This product is widely used in circulating water systems, air conditioning and refrigeration systems, heat exchange systems and hot water boiler systems in the construction, chemical, electric power, metallurgy, rubber, textile, food, and refrigeration industries.

Using the huge energy contained in the NdFeB rare earth permanent magnet material, the optimized design can form a vertical center magnetic field with multiple peaks. When the water or fluid flows through the vertical magnetic field at a speed of ≥51.5 m/s, an electromotive force will be generated to refine the crystal lattice, that is, the particle size of the scale crystal particles in the raw water changes from about 3.39 microns to about 0.22 microns , And the faster the flow rate, the greater the electromotive force generated, the more ideal the treatment effect, so as to achieve the purpose of anti-scaling and descaling.

The internal magnetic water processor uses the magnetic field to treat the water and changes the physical structure of the water without changing the chemical composition of the water, so as to achieve the purpose of anti-scaling, descaling, sterilization, algae killing, anti-corrosion and anti-rust water. . This is a physical method of water treatment, with good effect, low cost, no maintenance and no pollution. This product is widely used in circulating water systems, air conditioning and refrigeration systems, heat exchange systems and hot water boiler systems in the construction, chemical, electric power, metallurgy, rubber, textile, food, and refrigeration industries.

Using the huge energy contained in the NdFeB rare earth permanent magnet material, the optimized design can form a vertical center magnetic field with multiple peaks. When the water or fluid flows through the vertical magnetic field at a speed of ≥51.5 m/s, an electromotive force will be generated to refine the crystal lattice, that is, the particle size of the scale crystal particles in the raw water changes from about 3.39 microns to about 0.22 microns , And the faster the flow rate, the greater the electromotive force generated, the more ideal the treatment effect, so as to achieve the purpose of anti-scaling and descaling.

The principle of sterilization and algae killing

Because the NdFeB magnetic field of the internal magnetic water processor produces turbulent flow in the water wave, it destroys the ion channel of the cell membrane, changes the internal control current that the cell adapts to and the environmental conditions required for survival, and causes it to lose its viability and die. At the same time, the magnetically excited water molecules can surround and block the dissolved oxygen in the water, destroying the source of oxygen required for microorganisms to carry out life reactions, thereby achieving good sterilization and algae killing effects and preventing the production of biological sludge.

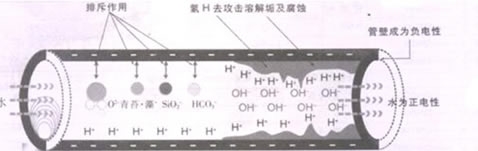

Anti-rust and anti-corrosion principle

Metal corrosion requires oxygen, and the action of high-frequency electromagnetic energy makes a single water molecule encapsulate the oxygen molecules dissolved in water, making the dissolved oxygen into inert oxygen, and blocking the source of oxygen required for metal corrosion. At the same time, the high-frequency electromagnetic wave excites the "skin effect" generated by the electromagnetic field of the pendant compound modulation frequency, which accumulates excess negative charges on the tube wall and excess positive charges inside the water. The positive charge strongly repels the positively charged Fe3+ of the same sex, preventing Fe from losing electrons to become Fe3+, which is separated from the metal tube wall and enters the water; at the same time, the excess negative electrons on the tube wall also continuously attract the positively charged Fe3+, preventing Fe3+ from dissolving into the water. ; So that the Fe2O3 (red rust) on the original tube wall is reduced to the black rust outer film Fe3O4 with strong corrosion resistance.

The effect of water treatment

Scope of application

ΔVarious water systems that are prone to bacteria, algae and scale.

Δ Air conditioning, refrigeration circulating water system.

ΔVarious heat exchange and cooling tower systems.

Δ Swimming pool system.

Technical Features

ΔHigh efficiency: It can improve the thermal efficiency by more than 20%, and the equipment does not need to be cleaned for continuous operation.

ΔSafety: Low working voltage.

ΔEnvironmental protection: no chemicals, no secondary pollution.

ΔEnergy saving, water saving, long life, can run continuously for more than 15 years. Small size, easy to install, no management required.

ΔThe investment is small, the recovery is fast, and the central air-conditioning system recovers the full cost in 1 to 2 years. The industrial water system can fully recover the cost within half a year.

Internal magnetic water processor specifications and operating parameters

Technical Features

ΔHigh efficiency: It can improve the thermal efficiency by more than 20%, and the equipment does not need to be cleaned for continuous operation.

ΔSafety: Low working voltage.

ΔEnvironmental protection: no chemicals, no secondary pollution.

ΔEnergy saving, water saving, long life, can run continuously for more than 15 years. Small size, easy to install, no management required.

ΔThe investment is small, the recovery is fast, and the central air-conditioning system recovers the full cost in 1 to 2 years. The industrial water system can fully recover the cost within half a year.

Internal magnetic water processor specifications and operating parameters

| Model Specifications | In and out diameter | Dimensions | flow | vertical center | medium work | weight | |

| mm | in | Diameter×Length | m3/h | Strong magnetismmt | temperature ℃ | kg | |

| YLC-1 | 25 | 1 | 108×330 | 4.9 | 160 | 0-90 | 10 |

| YLC-1.5 | 40 | 1.5 | 108×330 | 12 | 160 | 0-90 | 20 |

| YLC-2 | 50 | 2 | 159×450 | 19 | 160 | 0-90 | 30 |

| YLC-2.5 | 65 | 2.5 | 159×450 | 28 | 160 | 0-90 | 40 |

| YLC-3 | 80 | 3 | 159×450 | 50 | 160 | 0-90 | 45 |

| YLC-4 | 100 | 4 | 219×560 | 80 | 160 | 0-90 | 50 |

| YLC-5 | 125 | 5 | 219×600 | 125 | 160 | 0-90 | 60 |

| YLC-6 | 150 | 6 | 273×740 | 180 | 160 | 0-90 | 70 |

| YLC-8 | 200 | 8 | 325×790 | 320 | 160 | 0-90 | 90 |

| YLC-10 | 250 | 10 | 377×850 | 480 | 160 | 0-90 | 110 |

| YLC-12 | 300 | 12 | 426×900 | 600 | 160 | 0-90 | 130 |

| YLC-14 | 350 | 14 | 478×950 | 750 | 160 | 0-90 | 160 |

| YLC-16 | 400 | 16 | 530×1000 | 850 | 160 | 0-90 | 210 |

| YLC-18 | 450 | 18 | 620×1050 | 950 | 160 | 0-90 | 260 |

| YLC-20 | 500 | 20 | 720×1100 | 1100 | 160 | 0-90 | 260 |

Related Products

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible